Developing End-to-End Automation

As an MMT company, Somex is proud to be part of its automation division. This division comprises a team of expert engineers specializing in automating and integrating new and existing production lines for the medical device manufacturing industries. We develop cutting-edge automation technology and processes that can help streamline operations, increase efficiency, and improve our customer’s bottom line.

Somex Automation Portfolio includes:

- Catheter Coating & UV Curing

- Catheter UV Bonding

- Catheter Thermal Bonding

- Catheter Slotting

- Catheter Lamination

- Catheter & Tube Cutting and Coiling

- Marker Band Processing

- Flaring Equipment

- Necking Equipment

- Leak Testing

- Tube Stretching

- Balloon Forming

- Balloon Wing Forming

- Stent Deployment Testing

- Drug Eluting Stent Processing

- Vacuum Systems

- Coil Winding

- Stent Crimping

- Stent Handling

- Annealing Furnaces

- Product Functional Test

- Knotting and Suture-based Processes

- Stent Crimping & Loading

- Curing Chambers

1

1

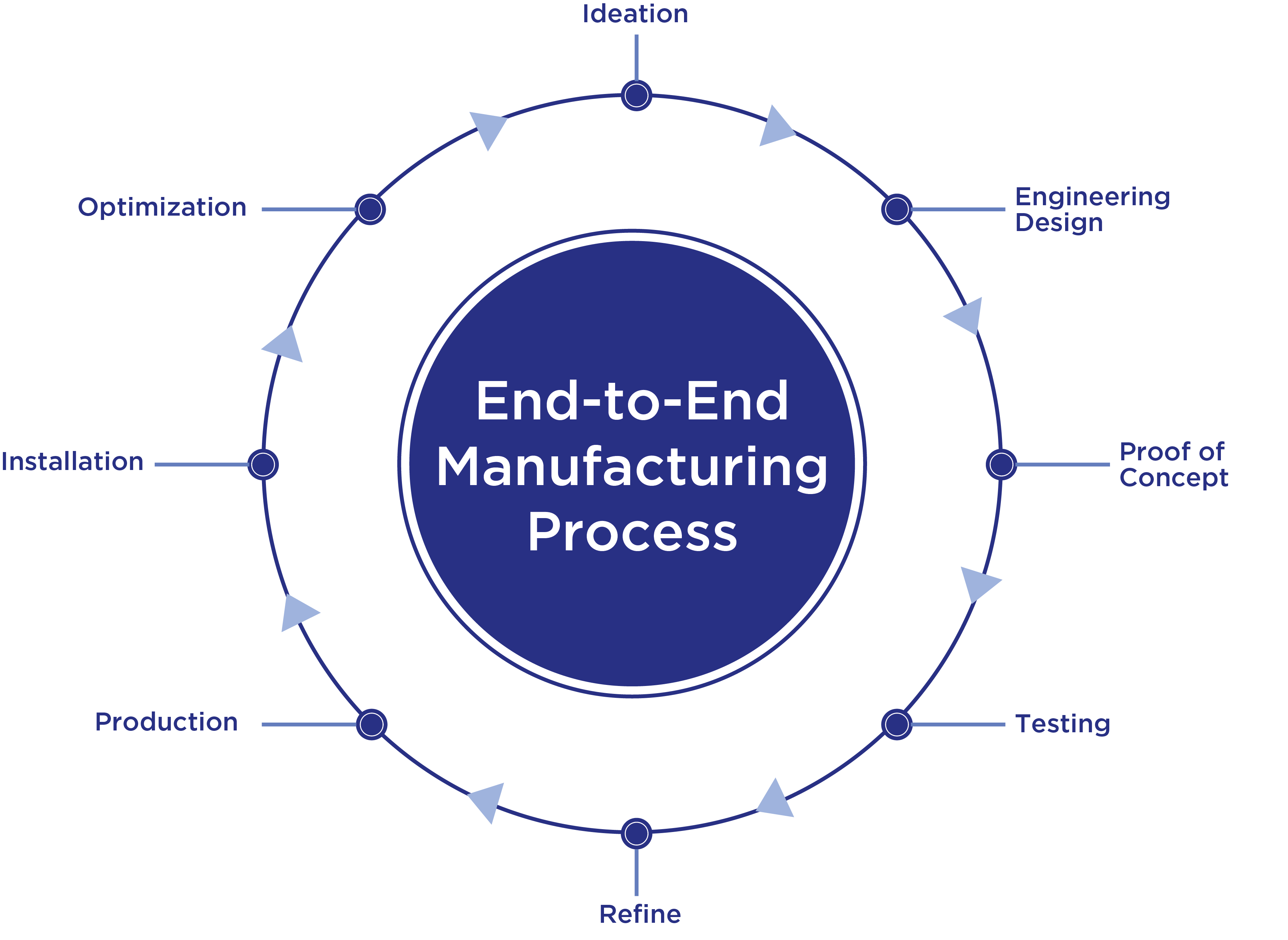

Now that you have conceptualized a process or device to solve a problem or enhance a current solution our team of skilled engineers are here to help you make it a reality.

Our team of highly skilled engineers will apply their expertise to conceptualize, design, and develop a solution that aligns with your exact specifications.

Our team of skilled engineering professionals specializes in creating reliable proof-of-concepts and prototypes, which are crucial for showcasing the feasibility and benefits of your product, process, or solution.

In order to ensure high-quality results, it is important to test your product or process in real-world conditions to identify and mitigate potential risks.

Our team understands that it may be necessary to refine a process to ensure quality standards and output are met.

Our experienced team of engineers work closely with you to ensure that your equipment solutions & processes are optimized and meet all regulations and standards.

We are dedicated to providing you with comprehensive installation services and support to ensure that your equipment solution is optimized to your exacting requirements on day one.

At MMT, we work tirelessly to optimize your product and processes, keeping you competitive now and in the years to come.

Catheter Products Include:

- Balloon Angioplasty

- Coronary and Peripheral Catheters

- Stent Delivery Systems (balloon and self-expanding)

- Urinary Catheters

- Structural Heart Products

Medical Implants Include:

- Stents (coronary, peripheral and non-vascular)

- Drug/Device Combination Products

- Neurovascular Implants

- Structural Heart Products

- Coil-based Products

VISIONPICK HANDLING SYSTEM

Somex Automation developed the “VisionPick” standard platform for providing Machine Vision Guiding of Pick & Place equipment.

Watch the video or read more details on our case study page.

STATION

LAMINATOR

- Lamination of short sections of a catheter shaft with precise location and control of the product.

- Product lamination length is customized to suit the customer’s requirements.

- Product tooling is customized to suit the customer’s requirements.

Watch the video or read more on our case study page.

DOUBLE DECK COMBI LAMINATOR

Somex Automation designs precision catheter manufacturing solutions. The Double Deck Combi Laminator is capable of laminating multiple catheter shafts simultaneously.

Watch the video or read more on our case study page.

SURFACE SCANNING & LASER DEPOSITION

Integration of multiple systems in a complete Cell for Metal Deposition on highly targeted & specific regions of metal components.

- Metal Component Processing.

- Additive Machining principle.

- 3D Laser scanner builds CAD model of substrate actual surface.

Watch the video or read more details on our case study page.

Qualification and Validation

At Somex Automation, we ensure that all equipment is rigorously tested and documented in-house using GAMP 5 procedures. With dedicated quality departments on both our sites, we are positioned to support our customers through their entire qualification and validation process, from the placement of order to production.

Comprehensive technical documentation is supplied with our equipment, which provides the client with the necessary information for operating, troubleshooting and maintenance of the equipment.